Murphy Maverick

Electric Drive System Retrofit

Project Abstract

With the mounting global pressures to move away from a fossil fuel economy, it is only a matter of time before “green” technology becomes more widespread within the aerospace industry. While I was working at Murphy Aircraft Manufacturing, the company was approached by the Nation Research Council of Canada (NRC) to conduct a feasibility study for an electric drive system retrofit on the existing Murphy Maverick air frame. This air frame was determined to be the lightest air frame produced by Murphy Aircraft that could be outfitted with an electric drive system. The preliminary phases of this project completed during my three month contract with Murphy Aircraft Manufacturing are listed below.

Marketability analysis

Identifying constraints and design parameters

Equipment selection

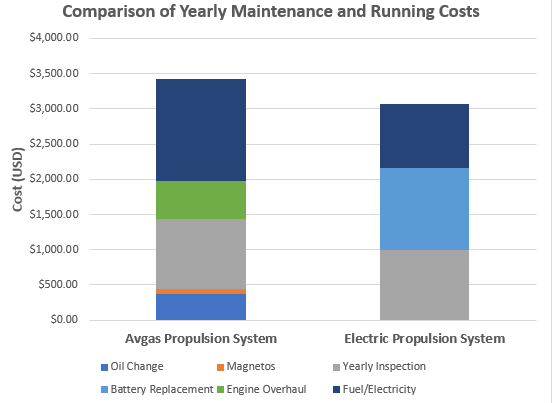

My work in Phase 1 consisted of a net GHG emissions comparison and yearly running cost comparison between Avgas and electric propulsion systems for the Murphy Maverick. Phases 2 and 3 of the project were my core responsibilities.

Ultimately, with the Murphy Maverick stripped to only include the equipment necessary to operate under Visual Flight Rules (VFR) and a polished aluminum finish instead of paint, the Murphy Maverick Electric Drive System Retrofit was found to be feasible for a single pilot cruising at 60 miles per hour. This result met our expectations given the current battery technology available.

Comparison of GHG emissions for an electric propulsion system and an Avgas propulsion system using a Rotax 503 engine.

Comparison of yearly maintenance and running costs.

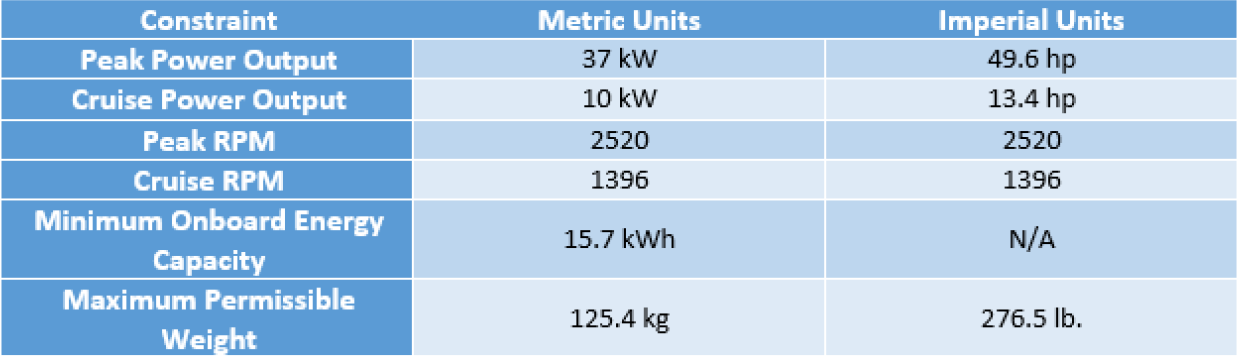

Identifying Constraints & Design Parameters

The constraints for the electric propulsion system design were derived from the aircraft performance targets which revolved around creating a safe, home-built, ultralight aircraft that was capable of cruising for at least 30 minutes. The most important performance parameters considered were,

Stall speed

Maximum takeoff weight

Cruise speed

The existing stall speed of the Murphy Maverick (30 mph) was taken to be the target stall speed because the goal was safety and the Maverick airframe was considered the benchmark for safety at Murphy Aircraft. The maximum take-off weight was limited to 1,200 pounds as stated by the Ultralight Aircraft Classification and the target cruise speed was set to 60 mph based on aerodynamic requirements and enjoyability. A target flight profile was constructed based on the flight experience of a coworker who was on the project and constraints for the electric drive system were derived from the flight profile.

A basic flight profile for a homebuilt ultralight aircraft.

Design constraints on the electric propulsion system.

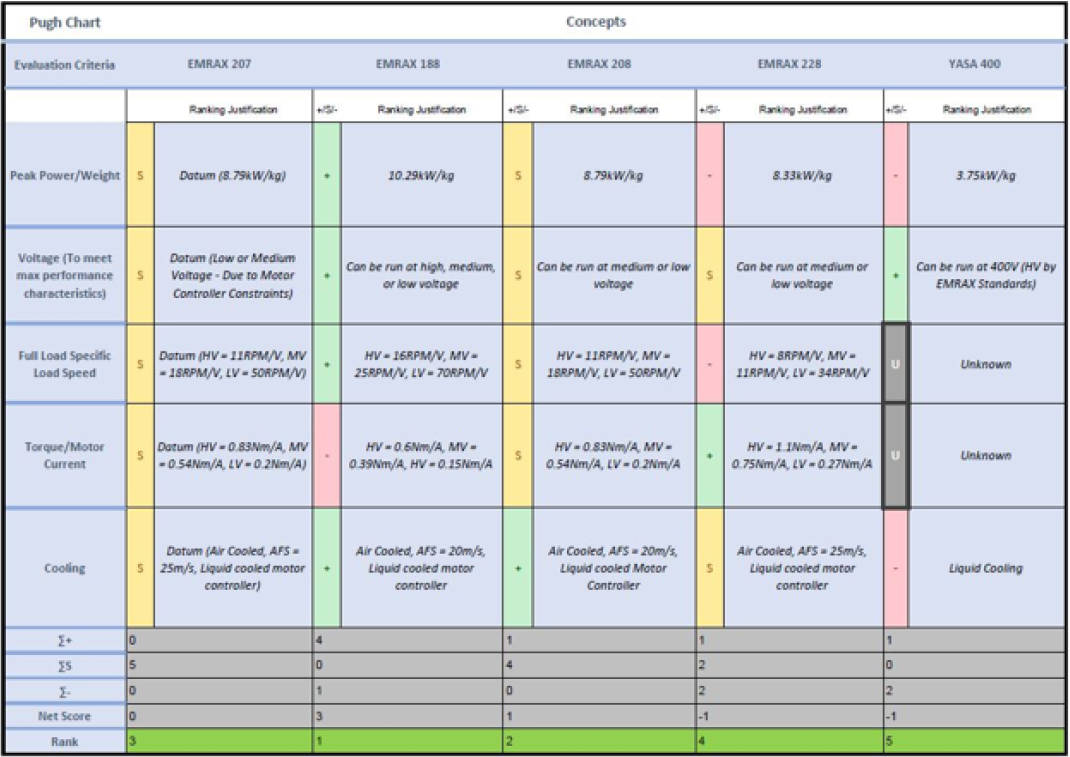

Equipment Selection

Equipment selection was done by conducting research on available equipment that could be used in an aircraft electric drive system and using a Pugh Chart to evaluate the available options. Since the drivetrain, motor and batteries were the most deterministic components of the system, the Pugh chart analysis was only conducted for these components.

A Pugh chart for the drivetrain selection.

A Pugh chart for the motor selection.

Results & Opportunities for Improvement

In conclusion, an electric drive system retrofit for the Murphy Maverick airframe was found to be feasible for the target specifications but there are still multiple improvements that could be made to the Maverick airframe. These improvements include,

Adding droop tips and velocity generators to improve lift-drag characteristics

Using a polished aluminum finish instead of paint to reduce weight

Increasing cabin width to allow for side-by-side seating and tricycle landing gear to improve marketability